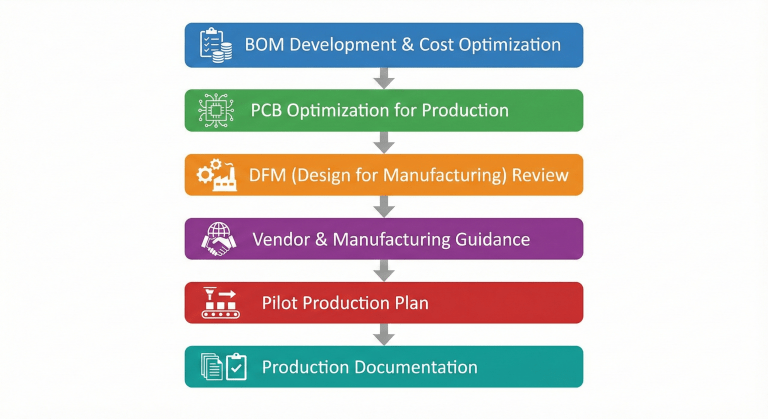

Prototype to Production

BOM Development & Cost Optimization

We prepare a complete component list with:

Component name, specs, part number

Vendor recommendations (India + global)

Cost per unit (prototype & bulk at 100 / 500 / 1000 qty)

Availability & lead time

Alternatives for high‑risk components

We analyze:

Cost reduction possibilities

Substitutions for expensive parts

Import vs local sourcing

PCB Optimization for Production

We improve the prototype PCB into a production‑grade board:

Size reduction

Noise reduction

Routing optimization

Thermal management

EMI/EMC considerations

Connector placement for assembly

Edge cuts, mounting holes, antenna clearance

DFM (Design for Manufacturing) Review

We evaluate the entire product for manufacturing efficiency:

Can components be assembled easily?

Are solder joints reliable?

Is the enclosure manufacturable?

Are tolerances correct?

Is cable management clean?

Are parts easy to align and fit?

We work with your mechanical designer or provide guidance on:

Mold design (if plastics are used)

Draft angles, wall thickness, ribs

Snap‑fits vs screws

Waterproofing (IP ratings)

Vendor & Manufacturing Guidance

We guide you through all choices:

PCB fabrication vendor

SMT assembly vendor

Plastic mold manufacturer

Final assembly unit

We also advise on:

NRE (Non‑Recurring Engineering) costs

MOQ requirements

Lead times

Quality control methods

Pilot Production Plan

Before full production, we plan a pilot batch:

10–100 units

Testing SOPs

QC processes

Failure analysis

Field deployment strategy

This validates:

Assembly reliability

Component consistency

Real usage performance

Production Documentation

We prepare essential documents:

Gerber files

Assembly drawings

Wiring diagrams

Firmware loading guide

Testing checklist

QC process document